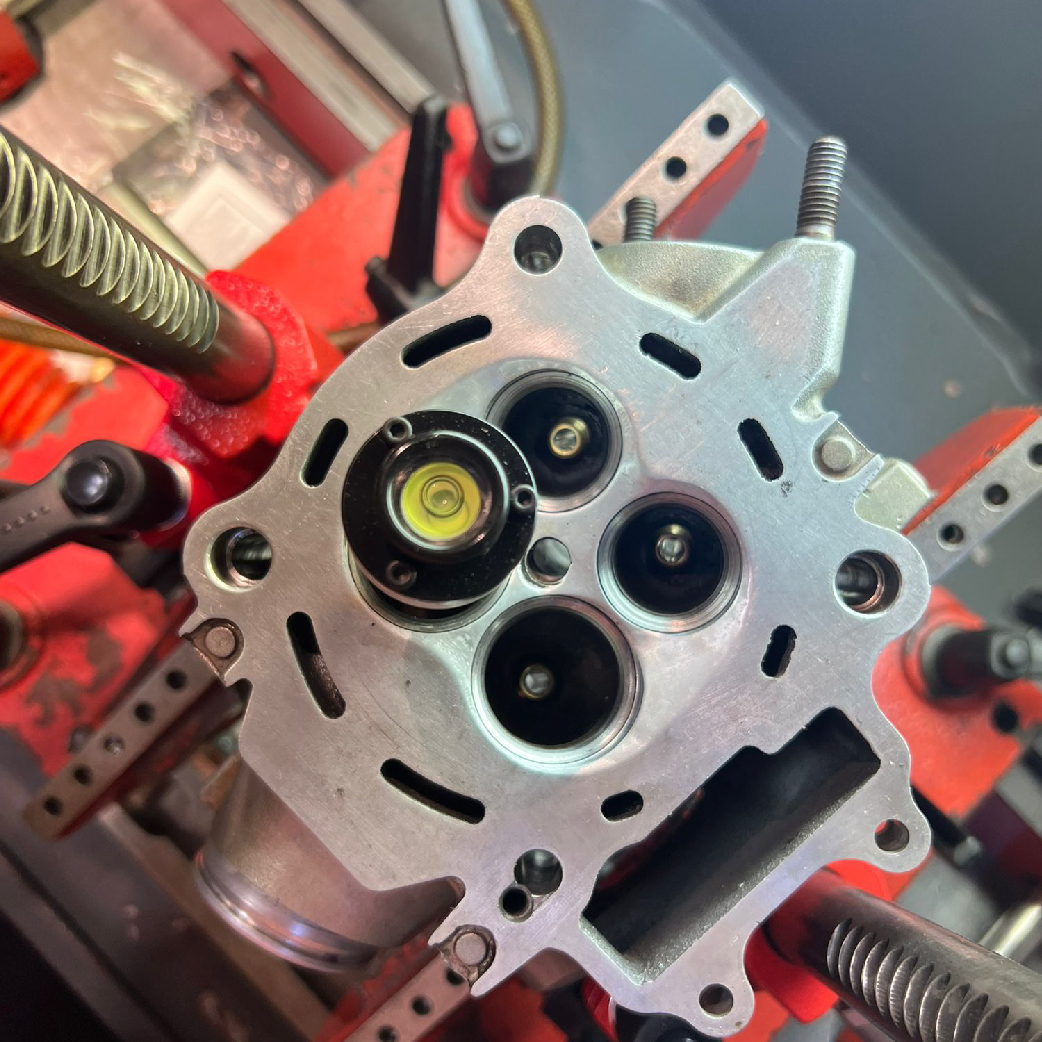

HAVING VALVE ISSUES?

Constant shimming, hard starts , hard

to start when hot, losing compression . The common issues is the titanium

valves have a special coating on the face , the powdered steel seats in the

head get harder as they are run longer , and usually start to flake , the heat

transfer of the stock seat material is no good. Best upgrade of seat material

for these heads are c630, moldstar 90 or beryllium copper. This will eliminate

all of your premature valve issues and end the having to constantly adjust

them. We run this set up in all our engines with little to no wear. Best

upgrade for the guides is the bronze manganese material. We have access to kibblewhite

valve, wiseco (who bought out exceldyne ) del west and ferrea valves. We can

also offer stainless swap kits which will also Eliminate your valves issues but

you will lose around 2hp and some rpm’s. With stainless we can keep your stock

seat material but your seats will need to be recut and vacuum tested to ensure

a adequate seal, we use a valve concentricity gauge after the seats are cut to

ensure correct valve/seat to guide concentricity. If you have any questions

feel free to ask.

PRICES ARE AS FOLLOWS FOR CYLINDER HEAD WORK

PRICES ARE AS FOLLOWS FOR CYLINDER HEAD WORK. These prices do not include any valve train parts, seat material, guides or valve seals.